Oxygen Shock (Potassium Monopersulfate)

Superchlorination alternative (Potassium Monopersulfate, Sodium Percarbonate)While alternative methods are gaining in popularity and acceptance, chlorine remains far and away the No. 1 sanitizer used in pools and spas .

Its time-tested ability to quickly kill nearly every microorganism that can cause disease is well known, disinfecting pool and spa water by killing pathogenic bacteria and viruses within seconds of application.

|

In addition to its sanitizing capabilities, chlorine is also widely used as an oxidizer, helping to rid the water of contamination that can be introduced from a variety of sources. These are generally recognized as bather wastes like urine and perspiration, cosmetic products, sunscreens and lotion. But they also include organic contaminants that can be introduced through wind and rain, such as dust, dirt, pollen, insects, plant and grass debris and airborne pollutants.

The sanitizer works hard at oxidizing — or burning up — these contaminants, but as they build up in the pool water, they combine with the sanitizer in the water to produce what we call chloramines or bromamines.

In the case of chloramines, they can cause a foul smell and can lead to cloudy, dull water. While still a killing forn of sanitizer, the effectiveness of this combined form of chlorine is minimized and, if left unattended, can lead to poorer and poorer water quality and algae headaches.

One of the problems that occurs automatically is that when these contaminants are introduced into the water, the sanitizer — which should be working on killing bacteria and virus — shifts and tries to do its secondary job as an oxidizer. Chemically, we say that there is a sanitizer demand.

Unfortunately, as the sanitizer is called upon to oxidize to destroy organic contaminants, its efficiency as a disinfectant is significantly reduced.

To overcome the buildup of the combined forms of sanitizer, the industry standard has been to superchlorinate or shock the water. In this process, the chlorine level is raised to about 10 times the normal readings on a chemical test to reach what is, called breakpoint.

At this point, the chloramines are broken down, bringing the chlorine

back to its free — and best killing form.

It is common, however, for a small amount of combined chlorine to remain

in the water after a corrective breakpoint has been reached, especially

when organic nitrogen compounds are present in the pool water. Also

— in the real world — chlorine will continue to combine with contaminants

that constantly enter the water, and almost immediately again begin

forming chloramines. So realistically, you can never totally rid the

water of chloramines.

Another common problem, of course, is finding the proper level of chlorine

you must add to reach this breakpoint. As you add chlorine, you are

effectively raising he chloramine level even higher and higher in the

pool. And if you fail to reach breakpoint, you are simply increasing

the undesirable effects.

Also, high chlorine levels in the pool can cause significant down time

while normal levels are returned, or you may need to revisit the pool

to dechlorinate.

What's a pool pro to do?

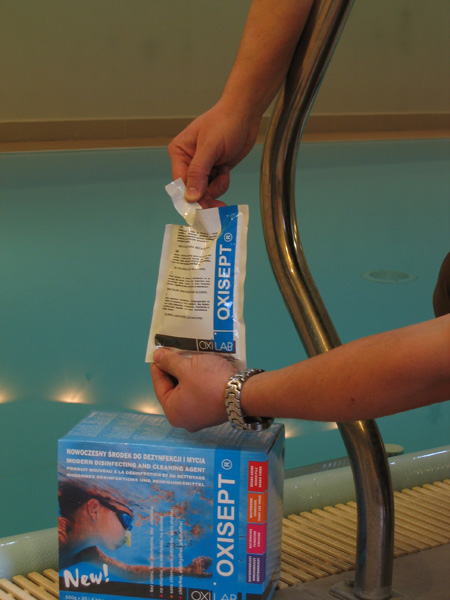

One way that pool operators are be ginning to overcome the problem

is through use of a non-chlorine shock — most notably potassium monopersulfate

— to shock their pools. And rather than waiting for combined chlorine

readings to rise above proper levels, they are using monopersulfates

on a regular basis as a preventative measure to oxidize contaminants

before they combine to cause water quality problems.

In addition to potassium monopersulfate , other oxygen-based shocking chemicals could include sodium persulfate, sodium carbonate peroxyhydrate (also known as sodium percarbonate ) and hydrogen peroxide. Sodium persulfate has about the same active oxygen content as potassium monopersulfate, but has a low reactivity and also can cause a chemical buildup in indoor pools. The other two have high active oxygen content and are commonly used in dechlorination.

The advantages to oxidation without chlorine include that fact that there is no added production of chloramines and sanitizer efficiency is increased without raising the chlorine level. The chlorine ÿ without its added duty as an oxidizer — is free to do its job as a bacteria killer. At the same time, monopersulfates accelerate chloramine degradation.

With regular, preventative use, you end up with better water quality, longer periods of uninterrupted swim time, and a more manageable maintenance schedule.

Potassium monopersulfate is a strong, odorless, oxygen-based oxidizer that works well with sanitized chlorine, bromine and most alternatives. Unaffected by UV degradation, non-chlorine shock can be added to pool water day or night, and swimming can resume after just a short waiting period.

The product is fast dissolving, and when broadcast uniformly over the water with the circulation system running, it will quickly mix into solution with the pool water. Because of its characteristics, monopersulfates will not damage or fade vinyl liners.

Recommended doses are one pound per 10,000 gallons of pool water, but more frequent and higher doses may be useful in commercial pool applications. In spas, manufacturers recommend oxidizing with non-chlorine shock after each use. Recommended dosage for spas is 1-2 ounces per 250 gallons.

Shaoxing Biotech Chemical Co Ltd, the manufacturer of potassium monopersulfate , recommends its use on a regular basis rather than waiting for problems to occur. Their reasoning is simple: If the condition of your pool water is so bad that it needs shocking, something has already gone amiss. And you don't have to be a chemist to know that it makes more sense to prevent a problem in the first place that it does to try to fix one once it has occurred.

The rationale of using this preventative medicine for your customers' pools is a strong one. When the quality of water deteriorates to such a degree that shocking becomes necessary, are you really sure that you are providing enough sanitation?

And during the time you are superchlorinating, your pools may be unusable, which can be especially troublesome in commercial pools. In addition, the work associated with corrective action can be significantly more time consuming than the few minutes added to your routine maintenance schedule to add non-chlorine shock on a regular basis.

When winterizing using a non-chlorine shock can help to prolong the sanitizer residual, which can be a benefit as the pool remains idle for several months on end. The shock treatment accomplishes this by oxidizing wastes and thus "freeing up" the chlorine or bromine to do its job as a disinfectant. Potassium monopersulfate does not, however, kill bacteria and cannot replace your choice of sanitized. And because of its acidic nature, regular use will also lower pH and total alkalinity. Soda ash or bicarbonate should be added to maintain acceptable levels of pH and alkalinity.

When testing, you should be aware that while no interference will be detected when using OTO test kits, there is minimal interference with free chlorine readings on DPD tests. The DPD reacts with the potassium in the total chlorine test to give a false high combined chlorine reading, but there are test kits available to eliminate monopersulfate interference.

When using test strips, service professional should be aware that while there is no interference with free chlorine readings, the potassium can react with total chlorine and total bromine tests.

Monopersulfate compounds — even when used on a regular basis as part of a prevention program — are not a cure all for water problems. Naturally, you still need to consider: Circulation — your pumps and filters should be properly sized for adequate flow and turnover rates.

Condition of the filter elements and media needs to be properly maintained to assure maximum effectiveness.

Regular vacuuming to prevent the buildup of particles that make the water cloudy.

Water balance — Are pH, alkalinity or calcium hardness levels too high? These situations can lead to cloudy water problems.

With these considerations addressed and problems persisting, may need to consider addition of water clarifiers or other preventative specialty chemicals to maximize water quality.

But routine shocking to allow sufficient free available sanitizer and minimize the problems taht can develop with combined forms of chlorine or bromine can go a long way to controlling problems before occur.